Specifications of Welding Wire:

Made in accordance with norms of ASTM ,JIS,GB : Also our TIG wires strictly conform to the standards and specifications of American Welding Society (AWS) and are manufactured in the SS grades AISI 307, 307Si, 308, 308H, 308L, 308LSi, 309, 309L, 309LSi, 309LMo, 310, 312, 316, 316H, 316L, 316LSi,317, 317Si, 318Si, 321, 347, 347Si, 409, 409Cb, 409Ti, 410, 410NiMo, 420, 430, 430LNb, 904L, 2209.

Standard: GB, SUS, AWS, JIS, DIN, BS970

Surface: Bright, Cloudy,Plain,Black

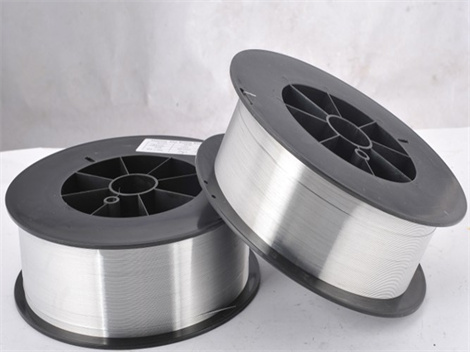

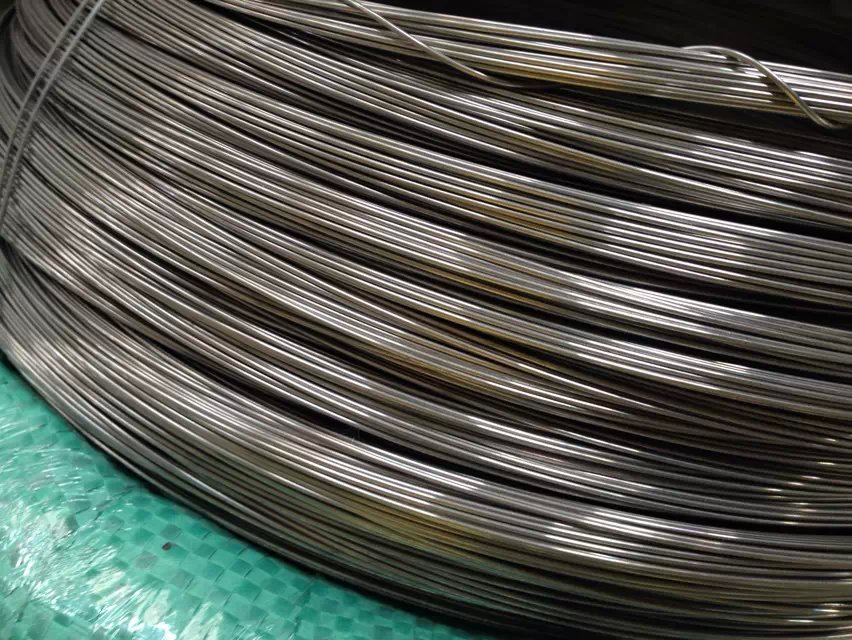

ALLIN METAL’S Stainless steel welding wires for TIG in straight , MIG on spools and Core wire on coils:

| Wire Type |

Size Available |

Package way |

Net weight |

| MIG Wire: |

0.8mm-1.6mm |

D100/ D200/ D270/ D300 |

1kgs/5kgs/12.5kgs/15kgs/20kgs |

| TIG Wires: |

1.6mm-5.5mm |

1meter/plastic drum |

5kgs/10kgs |

| Core Wire: |

1.6mm-6.0mm |

Coil / Drum |

30-500kgs |

Common Grade of ER Stainless Steel Welding wires:

| MODE |

CHEMICAL COMPOSITION (%) |

| C (max) |

Si (max) |

Mn (max) |

P(max) |

S(max) |

Cr |

Ni |

Mo |

Cu |

| ER308 |

0.08 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

19.5-22.0 |

9.0-11.0 |

0.75 |

0.75 |

| ER308L |

0.03 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

19.5-22.0 |

9.0-11.0 |

0.75 |

0.75 |

| ER308LSI |

0.03 |

0.65-1.0 |

1.0-2.5 |

0.03 |

0.03 |

19.5-22.0 |

9.0-11.0 |

0.75 |

0.75 |

| ER309 |

0.12 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

23.0-25.0 |

12.0-14.0 |

0.75 |

0.75 |

| ER309L |

0.03 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

23.0-25.0 |

12.0-14.0 |

0.75 |

0.75 |

| ER310 |

0.08-0.15 |

03-0.65 |

1.0-2.5 |

0.03 |

0.03 |

25.0-28.0 |

20.0-22.5 |

0.75 |

0.75 |

| ER312 |

0.15 |

0.3-0.62 |

1.0-2.5 |

0.03 |

0.03 |

28.0-32.0 |

8.0-10.5 |

0.75 |

0.75 |

| ER316 |

0.08 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

18.0-20.0 |

11.0-14.0 |

2.0-3.0 |

0.75 |

| ER316L |

0.03 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

18.0-20.0 |

11.0-14.0 |

2.0-3.0 |

0.75 |

| ER316LSI |

0.03 |

0.65-1.0 |

1.0-2.5 |

0.03 |

0.03 |

18.0-20.0 |

11.4-14.0 |

2.0-3.0 |

0.75 |

| ER410 |

0.12 |

0.50 |

0.60 |

0.03 |

0.03 |

11.5-13.5 |

0.6 |

0.75 |

0.75 |

| ER430 |

0.10 |

0.50 |

0.60 |

0.03 |

0.03 |

15.5-17.0 |

0.6 |

|

|

| ER2205 |

0.03 |

1.00 |

2.00 |

0.03 |

0.02 |

22.0~23.0 |

4.5~6.5 |

3.0~3.5 |

|

| ER2209 |

0.03 |

0.90 |

0.5-2.0 |

0.03 |

0.03 |

21.5-23.5 |

7.5-9.5 |

|

|

| ER2553 |

0.04 |

1.00 |

1.50 |

0.04 |

0.03 |

24.0-27.0 |

4.5-6.5 |

|

|

| ER2594 |

0.03 |

1.00 |

2.50 |

0.03 |

0.02 |

24.0-27.0 |

8.0-10.5 |

|

|

Specifications of Welding Wire:

Made in accordance with norms of ASTM ,JIS,GB : Also our TIG wires strictly conform to the standards and specifications of American Welding Society (AWS) and are manufactured in the SS grades AISI 307, 307Si, 308, 308H, 308L, 308LSi, 309, 309L, 309LSi, 309LMo, 310, 312, 316, 316H, 316L, 316LSi,317, 317Si, 318Si, 321, 347, 347Si, 409, 409Cb, 409Ti, 410, 410NiMo, 420, 430, 430LNb, 904L, 2209.

Standard: GB, SUS, AWS, JIS, DIN, BS970

Surface: Bright, Cloudy,Plain,Black

ALLIN METAL’S Stainless steel welding wires for TIG in straight , MIG on spools and Core wire on coils:

| Wire Type |

Size Available |

Package way |

Net weight |

| MIG Wire: |

0.8mm-1.6mm |

D100/ D200/ D270/ D300 |

1kgs/5kgs/12.5kgs/15kgs/20kgs |

| TIG Wires: |

1.6mm-5.5mm |

1meter/plastic drum |

5kgs/10kgs |

| Core Wire: |

1.6mm-6.0mm |

Coil / Drum |

30-500kgs |

Common Grade of ER Stainless Steel Welding wires:

| MODE |

CHEMICAL COMPOSITION (%) |

| C (max) |

Si (max) |

Mn (max) |

P(max) |

S(max) |

Cr |

Ni |

Mo |

Cu |

| ER308 |

0.08 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

19.5-22.0 |

9.0-11.0 |

0.75 |

0.75 |

| ER308L |

0.03 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

19.5-22.0 |

9.0-11.0 |

0.75 |

0.75 |

| ER308LSI |

0.03 |

0.65-1.0 |

1.0-2.5 |

0.03 |

0.03 |

19.5-22.0 |

9.0-11.0 |

0.75 |

0.75 |

| ER309 |

0.12 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

23.0-25.0 |

12.0-14.0 |

0.75 |

0.75 |

| ER309L |

0.03 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

23.0-25.0 |

12.0-14.0 |

0.75 |

0.75 |

| ER310 |

0.08-0.15 |

03-0.65 |

1.0-2.5 |

0.03 |

0.03 |

25.0-28.0 |

20.0-22.5 |

0.75 |

0.75 |

| ER312 |

0.15 |

0.3-0.62 |

1.0-2.5 |

0.03 |

0.03 |

28.0-32.0 |

8.0-10.5 |

0.75 |

0.75 |

| ER316 |

0.08 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

18.0-20.0 |

11.0-14.0 |

2.0-3.0 |

0.75 |

| ER316L |

0.03 |

0.3-0.65 |

1.0-2.5 |

0.03 |

0.03 |

18.0-20.0 |

11.0-14.0 |

2.0-3.0 |

0.75 |

| ER316LSI |

0.03 |

0.65-1.0 |

1.0-2.5 |

0.03 |

0.03 |

18.0-20.0 |

11.4-14.0 |

2.0-3.0 |

0.75 |

| ER410 |

0.12 |

0.50 |

0.60 |

0.03 |

0.03 |

11.5-13.5 |

0.6 |

0.75 |

0.75 |

| ER430 |

0.10 |

0.50 |

0.60 |

0.03 |

0.03 |

15.5-17.0 |

0.6 |

|

|

| ER2205 |

0.03 |

1.00 |

2.00 |

0.03 |

0.02 |

22.0~23.0 |

4.5~6.5 |

3.0~3.5 |

|

| ER2209 |

0.03 |

0.90 |

0.5-2.0 |

0.03 |

0.03 |

21.5-23.5 |

7.5-9.5 |

|

|

| ER2553 |

0.04 |

1.00 |

1.50 |

0.04 |

0.03 |

24.0-27.0 |

4.5-6.5 |

|

|

| ER2594 |

0.03 |

1.00 |

2.50 |

0.03 |

0.02 |

24.0-27.0 |

8.0-10.5 |

|

|

Leave Your Message,Send Inquiry